Selecting a Burr Type for an Espresso Grinder

/By Chase Lemos, Nova Ricambi USA

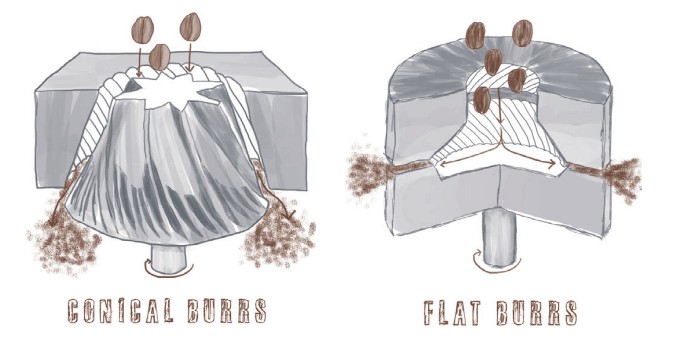

If we consider grinders to be an important yet under-appreciated facet of espresso preparation, then burrs are certainly an under-appreciated facet of what makes for a solid espresso grinder. There are two main burr types, flat burrs and conical burrs. As you may expect, they are different in several ways - noise, particle distribution, cost, heat, and grind retention.

Flat burrs are considered to be the louder burr of the two. This is because they require a faster rotation speed to do the same work. The faster rotation requires a larger motor which makes more noise due to its size. The faster rotation means that the coffee enters in the middle of the burr set and is ground over the teeth then ‘flung’ out of the chute. Conical burr grinders can be marginally quieter, and rotate more slowly due to their smaller motor resulting in a slower feeding of grounds through the chute.

Flat burrs have a different geometry than conical burrs (which is obvious when looking at them), the main focus here being the outfall depth. The outfall depth is the size of the hole created on the side of the burr when the tertiary cuts are aligned. The larger the outfall depth, the faster the burr will grind and the less consistent the particle distribution will be. That being said, the outfall depth of a flat burr is generally smaller than the outfall of a conical burr. This means that the ratio of fines to boulders is much closer together than it would be for a conical burr. As a result, at a macro level, flat burrs create a more uniform particle size than conical burrs. This can create a dichotomy in the coffee world. Is it better to have particles closer to uniform or is it better to have more fines in the mix? The fines will block the channel of the water flowing through the puck causing the water to soak the larger particles. The question becomes, does this create better espresso than a more uniform grind that will have a more even flow through the puck? There are some on both sides of the argument. I believe that both can be used to create great espresso but on a theoretical level I would take the conical burr. (Yet, somehow, both of my home grinders are flat-burred).

Flat burrs use less steel than conical burrs. This means that material cost of the burr set is lower for the flat burr. This increased cost seems to be realized when purchasing a grinder as well. Taking Mazzer as a baseline, we see the Kony is generally more expensive than the Major.

Flat burrs rotate faster creating more friction than conical burrs and use a larger motor to achieve that needed speed. Both of these factors create additional heat in the grinder. As a result, conical burrs should be cooler than flat ones.

Flat burrs have two potentials for grind retention [grinds remaining in the grinder after you have dosed your coffee (in a doserless grinder)]. These are in between the burrs themselves as the burrs stop spinning and on the ‘ledge’ between the edge of the burr and the chute. Due to the higher rotational speed of the burrs the engineers have used the burrs tendency to ‘fling’ coffee when they designed the grinder. If the burrs spin too slowly (as they will at start up and finishing of the grind) then grinds can fail to travel all the way to the chute. And as it slows down the grinds can fail to leave the burr at all. These stragglers will putrify given enough time and can impact the flavor of your espresso. As a result, flat burrs need to be cleaned more regularly than conical burrs to help remove the retained grounds. Conical burrs generally have a more vertical setup and grind directly above the chute. This means that the grinds are dropped more gently and with fewer retained grounds. In many cases, this results in a ‘fluffier’ presentation in the portafilter.

So, which burr is better? That is largely a matter of opinion. I have encountered good coffee brewed using both types of burrs. Understanding the positives and negatives of both systems is important to forming an informed opinion and thereby helping your client understand what they have and how to maintain.