Basic Functions of Thermosyphon Coffee Boilers in Espresso Machines

/By Stelios Apostolakis

The purpose of this presentation is to understand the basic functions of thermosyphon coffee boilers in espresso machines in order for the barista to make the most of them.

First of all, let us describe the phenomenon of thermosyphon (boiling) as well as why it is of the utmost importance when talking about espresso machines.

Thermosiphon (or thermosyphon) is a method of passive heat exchange, based on natural convection, which circulates a fluid without the necessity of a mechanical pump.

There is a cylindrical boiler(D) made of copper or stainless alloy which is filled with water to about 2/3 or 3/4 of its capacity. The rest is filled with steam. Inside, there is a completely submerged heating element that heats the water at a temperature sufficiently more than its boiling point. This water is used: a)for permanent steam inflow in the steam wands, b)for permanent hot water inflow in the water wand and finally and most important, c)for passively heating the HX/ Heat-Exchanger(B) so as to have hot water into the groups(A), being able to prepare our drink.

The HX is a pipe which is a part of a closed hydraulic system. While inactive, in other words without the pump (E) turned on, the water in it tends to raise its temperature at the same level with the surrounding water. By turning the pump on, we have a complex water boiling process as well as a blend of cold and hot, boiling water which is premeditated by the manufacturer. Everything is based on liquid thermodynamics, having as a result an appropriate extracting temperature.

It is the boiling function that keeps the group hot (approximately 100oC) while inactive. The hot water moves slowly but steadily from the highest level of the HX towards the group, where it cools and moves downwards by expelling heat, due to the small group thermal capacity. The water then regains its lost temperature since it enters the lowest part of the HX moving upwards……and goes round and round creating the necessary, for the function, thermal cycles.

Something very important that we should be aware of is that there is no, and there should be not any contact between the water in the cylindrical boiler (steam boiler) with the water in the HX pipe and the groups.

Let us make the Barista job easier by not only explaining the proper espresso machine function but also by explaining anything uncommon or unusual they may notice.

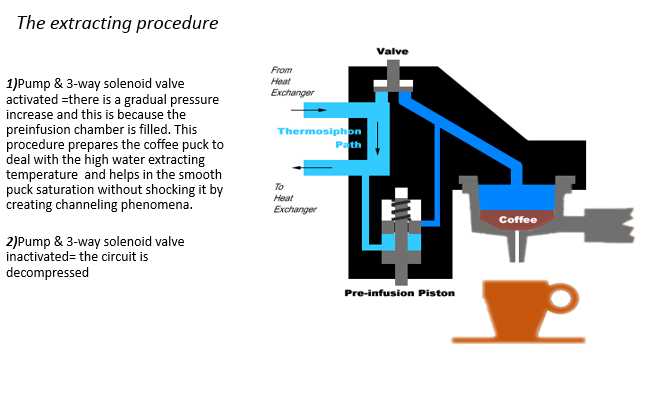

Let's begin the extraction procedure either dosimetrically or manually. The pump is activated and the 3-way solenoid valve is turned on. There is a gradual pressure increase and this is because the preinfusion chamber is filled. This procedure prepares the coffee puck to deal with the high temperature water and helps in the smooth puck saturation without shocking it by creating channeling phenomena. The manufacturer sets the necessary time in order for the chamber to be filled. This time is usually set at 4 sec. In terms of Barista, this is the "first drop". To conclude, if the whole routine procedure is right and the necessary time decreases, for example, to 2 seconds, then the chamber may be full of calcium deposits. By stopping the extracting procedure, the pump is inactivated. And the 3-way solenoid valve, through which the circuit is decompressed, forces the stagnant water and coffee to pour from the puck to the drainage.

To put it in a nutshell, if the 3-way solenoid valve did not exist in the circuit, then our cup would be filled with coffee sediments, ruining our beverage. This is my personal opinion, speaking as a technician, that's why I don't want to be misunderstood: the 3-way solenoid valve plays the most critical role in our extraction and this is because of the clean beverage,the clean cup of coffee. Thus, water droplets from the 3-way solenoid valve decompression when not being extracted, is a sign of repair (this is obvious mainly at the back part of the wastewater drainage). The safety valve for this function is called OPV(Over Pressure Valve or Relief Valve) and it does not let the building pressure due to the hydraulic resistance on the puck to exceed the safety limit of 11-14 bars (this depends on factors like the amount of coffee grams in the filter basket, type of grinding or the strength of tamping).

Concluding, I would like to point out how major the discovery of thermosyphon coffee boilers espresso machines is, since we can perform simultaneously two basic tasks in a single heating element, occupying the smallest possible volume. This is the reason why these machines have successfully accompanied the professionals for several decades now.

Technician and Barista: two sides of the same coin. The best cup possible.